Manufacturing

Not all electronic equipment is the same, the big difference is the quality of the components. quality of the components. On BOEL-TRONIC we invest a lot of time and effort to ensure that our products are of the highest quality. highest quality at the best cost.

Most of the products we offer are manufactured in our facilities, in order to achieve the highest quality control and verification in each of the production processes. This way of working gives us great confidence to carry out any new project, both in our own developments and in those we do for our clients.

We have the machinery and the necessary elements to offer you complete solutions for your projects.

Why work with us?

SMT ASSEMBLY

We carry out the assembly of SMD components through three independent lines consisting of:

These differentiated lines provide us with a great versatility in the assembly of prototypes, short, medium and long series for pcb’s of up to 1,500 mm in length.

CONVENTIONAL THT/MIXED ASSEMBLY

For circuits with mixed or only conventional assembly, we have a manual insertion line, and depending on each case, we proceed to the welding by means of:

The process is completed according to the customer’s specifications.

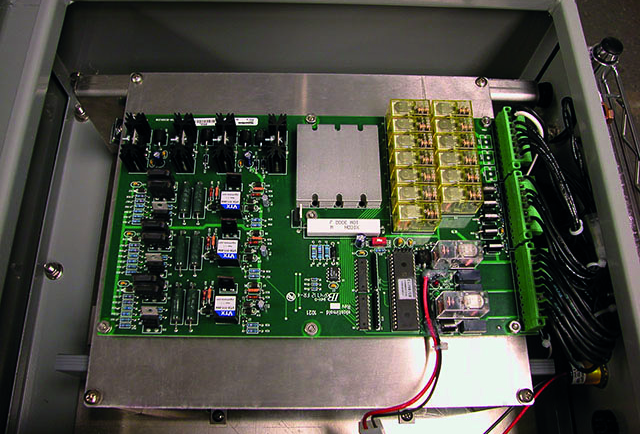

ELECTROMECHANICAL ASSEMBLY

We have three assembly lines, with extensive experience, with which we can adapt to your needs in:

WIRING AND CRIMPING OF TERMINALS

With high quality semi-automatic machines we perform the following works: